| Availability: | |

|---|---|

| Quantity: | |

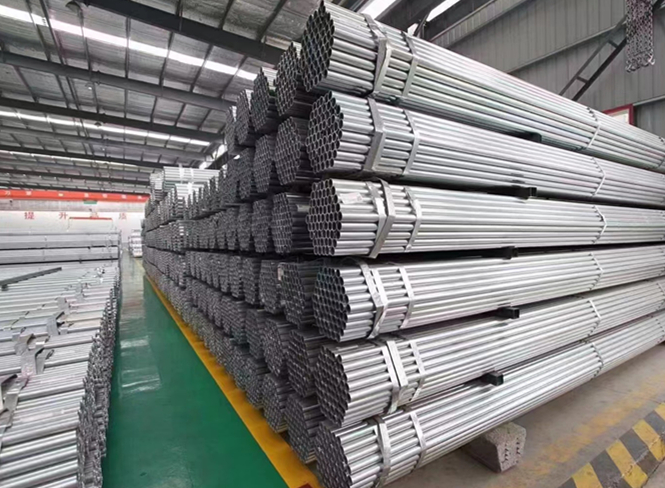

Tianjin Friend, a leading manufacturer and exporter, presents its premium range of Hot-Dip Galvanized Steel Pipes. These pipes are crafted with precision and undergo a rigorous hot-dip galvanizing process, ensuring a uniform and robust zinc coating on all surfaces. The result is a product that is not only visually appealing but also highly resistant to corrosion, making it an ideal choice for various industrial applications.

Tianjin Friend offers a wide range of welded hot-dip galvanized steel pipes with different standard. These pipes are thermally galvanized, meaning they are immersed to achieve a rough zinc coating on both the inside and outside surfaces. Unlike electro-galvanized pipes, all surfaces are treated. Galvanized pipes are manufactured according to the highest standards, EN39 for scaffolding pipes.

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm.

· S235GT Steel Grade: Aluminium tube requirment. Make it different from the common Q235 steel grade. Our steel tube is totally complying to the S235GT grade, ensuring quality and safety in every tube we produce, complying to the standard.

· Structural Reliability: Flattening test and bending test, with precise dimensions and exceptional mechanical properties, our tubes provide unwavering support.

· Durability: over 40 micron zinc coating. The hot dipped galvanized surface offers enhanced resistance to rusting, prolonging the service life of the scaffolding systems.

Our scaffolding tubes are manufactured to comply with various international standards such as EN39, ensuring quality and safety in construction projects. The production of these steel tubes involves strict testing to ensure their quality and performance. The thickness of the galvanized layer is usually not less than 40 microns. Product testing and compliance conform to the EN39:2001 grade S235GT or BS EN10219-1 grade S355JOH. We test the chemical components and tensile test every order and ensure all tubes complying to the S235GT steel grade. 3rd party test report will be provided to ensure the steel tube quality.

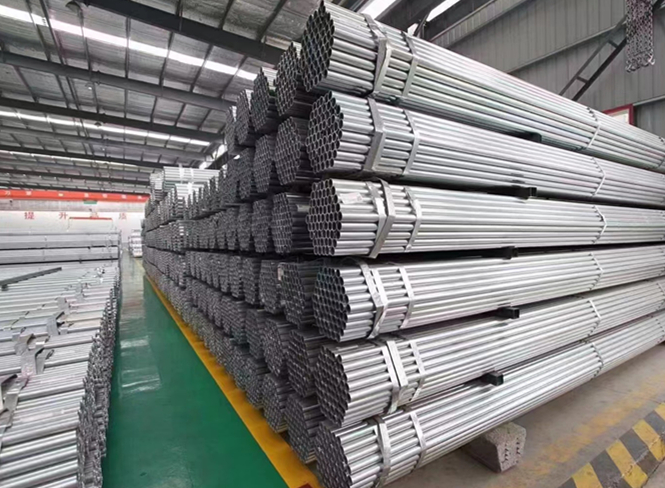

Tianjin Friend, a leading manufacturer and exporter, presents its premium range of Hot-Dip Galvanized Steel Pipes. These pipes are crafted with precision and undergo a rigorous hot-dip galvanizing process, ensuring a uniform and robust zinc coating on all surfaces. The result is a product that is not only visually appealing but also highly resistant to corrosion, making it an ideal choice for various industrial applications.

Tianjin Friend offers a wide range of welded hot-dip galvanized steel pipes with different standard. These pipes are thermally galvanized, meaning they are immersed to achieve a rough zinc coating on both the inside and outside surfaces. Unlike electro-galvanized pipes, all surfaces are treated. Galvanized pipes are manufactured according to the highest standards, EN39 for scaffolding pipes.

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm.

· S235GT Steel Grade: Aluminium tube requirment. Make it different from the common Q235 steel grade. Our steel tube is totally complying to the S235GT grade, ensuring quality and safety in every tube we produce, complying to the standard.

· Structural Reliability: Flattening test and bending test, with precise dimensions and exceptional mechanical properties, our tubes provide unwavering support.

· Durability: over 40 micron zinc coating. The hot dipped galvanized surface offers enhanced resistance to rusting, prolonging the service life of the scaffolding systems.

Our scaffolding tubes are manufactured to comply with various international standards such as EN39, ensuring quality and safety in construction projects. The production of these steel tubes involves strict testing to ensure their quality and performance. The thickness of the galvanized layer is usually not less than 40 microns. Product testing and compliance conform to the EN39:2001 grade S235GT or BS EN10219-1 grade S355JOH. We test the chemical components and tensile test every order and ensure all tubes complying to the S235GT steel grade. 3rd party test report will be provided to ensure the steel tube quality.

content is empty!