| Availability: | |

|---|---|

| Quantity: | |

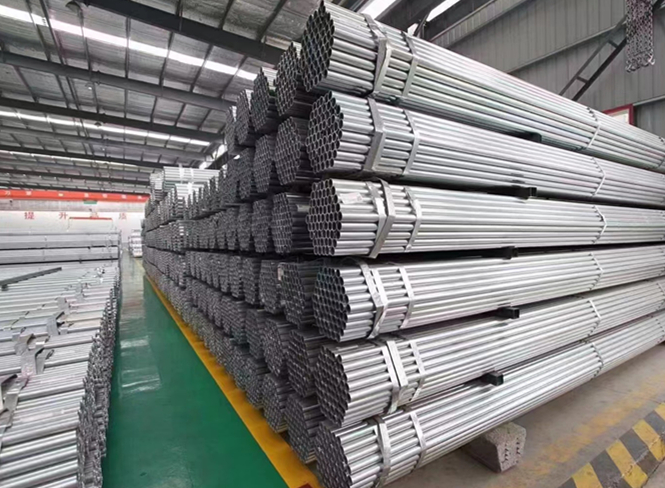

The EN 10219 standard is crucial for ensuring the safety and reliability of structural hollow sections used in various applications, from building frames to machinery supports. Compliance with this standard is a guarantee of quality and consistency in the manufacturing process.

The EN10219 scaffold tube is a type of steel tube with steel grade S355J0H commonly used for constructing scaffolding. These steel tubes have specific size and tolerance requirements, such as an outer diameter of 48.3mm, and wall thicknesses that can be 3.2mm with high tensile requirement. In terms of tolerances, the allowable deviation for the outer diameter is ±0.5mm, and the allowable deviation for the wall thickness is -10%.

Scaffolding tube is our stongr products with over 15 years' expereince. Our EN10219-compliant Scaffolding Tubes, meticulously crafted for the highest standards of structural integrity and safety. Our tubes are designed for the most demanding construction projects, offering superior performance and reliability.

Our scaffolding tubes are manufactured to comply with various international standards such as EN10219, ensuring quality and safety in construction projects. The production of these steel tubes involves strict testing to ensure their quality and performance. For instance, some manufacturers conduct tests on the chemical composition, physical properties, welding lines, and assembly inspections of the raw materials, and perform load capacity testing for all orders before production and shipment. These steel tubes are typically produced using the hot-dip galvanizing process to enhance their corrosion resistance and durability. The thickness of the galvanized layer is usually not less than 40 microns. Product testing and compliance conform to the EN39:2001 grade S235GT or BS EN10219-1 grade S355JOH. We test the chemical components and tensile test every order and ensure all tubes complying to the S355J0H steel grade.

Compliance with EN10219: Ensuring quality and safety in every tube we produce.

Structural Reliability: With precise dimensions and exceptional mechanical properties, our tubes provide unwavering support.

Durability: The fine-grain steel used offers enhanced resistance to wear and tear, prolonging the service life of the scaffolding systems.

Uniform Quality: Each tube is produced with consistent wall thickness and diameter, meeting stringent tolerances.

Galvanized Option: Available with a hot-dip galvanizing process for added corrosion resistance.

Versatile Usage: Suitable for a wide range of scaffolding applications, from temporary structures to permanent support systems.

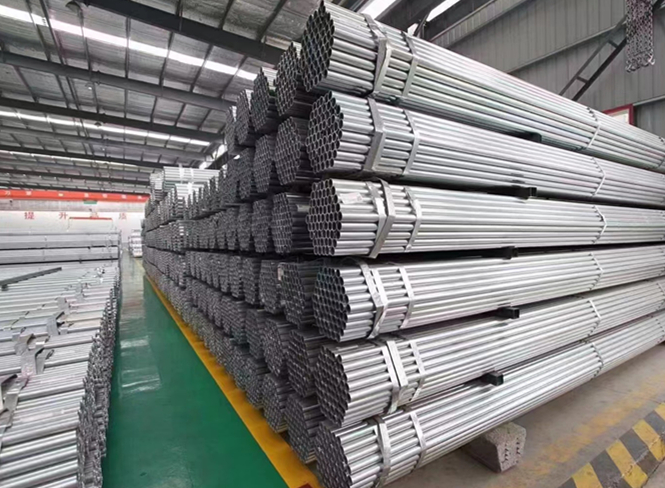

The EN 10219 standard is crucial for ensuring the safety and reliability of structural hollow sections used in various applications, from building frames to machinery supports. Compliance with this standard is a guarantee of quality and consistency in the manufacturing process.

The EN10219 scaffold tube is a type of steel tube with steel grade S355J0H commonly used for constructing scaffolding. These steel tubes have specific size and tolerance requirements, such as an outer diameter of 48.3mm, and wall thicknesses that can be 3.2mm with high tensile requirement. In terms of tolerances, the allowable deviation for the outer diameter is ±0.5mm, and the allowable deviation for the wall thickness is -10%.

Scaffolding tube is our stongr products with over 15 years' expereince. Our EN10219-compliant Scaffolding Tubes, meticulously crafted for the highest standards of structural integrity and safety. Our tubes are designed for the most demanding construction projects, offering superior performance and reliability.

Our scaffolding tubes are manufactured to comply with various international standards such as EN10219, ensuring quality and safety in construction projects. The production of these steel tubes involves strict testing to ensure their quality and performance. For instance, some manufacturers conduct tests on the chemical composition, physical properties, welding lines, and assembly inspections of the raw materials, and perform load capacity testing for all orders before production and shipment. These steel tubes are typically produced using the hot-dip galvanizing process to enhance their corrosion resistance and durability. The thickness of the galvanized layer is usually not less than 40 microns. Product testing and compliance conform to the EN39:2001 grade S235GT or BS EN10219-1 grade S355JOH. We test the chemical components and tensile test every order and ensure all tubes complying to the S355J0H steel grade.

Compliance with EN10219: Ensuring quality and safety in every tube we produce.

Structural Reliability: With precise dimensions and exceptional mechanical properties, our tubes provide unwavering support.

Durability: The fine-grain steel used offers enhanced resistance to wear and tear, prolonging the service life of the scaffolding systems.

Uniform Quality: Each tube is produced with consistent wall thickness and diameter, meeting stringent tolerances.

Galvanized Option: Available with a hot-dip galvanizing process for added corrosion resistance.

Versatile Usage: Suitable for a wide range of scaffolding applications, from temporary structures to permanent support systems.

content is empty!