| Availability: | |

|---|---|

| Quantity: | |

BS1139 scaffolding tubes are used across a range of construction and industrial applications, such as:

Supporting temporary work platforms in new builds and renovations.

Providing access for maintenance and repair tasks in industrial and commercial settings.

Serving as a backbone for stage and event structures, offering robust support.

BS1139 scaffolding tubes represent a commitment to excellence in temporary construction support solutions. Their adherence to a recognized standard, combined with their robust design and versatility, makes them a preferred choice for professionals in the construction industry seeking a reliable and safe scaffolding system

| Galvanized Steel Tube Scaffolding Pipe | |

OD | 1.5inch, 1-1/2", 48.3mm, 48.3mm |

Thickness | 3.2mm, 4.0mm |

Length | 1-6m, 5"-21" |

Material | Q235, S235GT, |

Standard | BS1139, EN10025, EN39, EN10219, JIS G3444 |

Surface | hot dipped galvanized |

Zinc Coating | 180-600g |

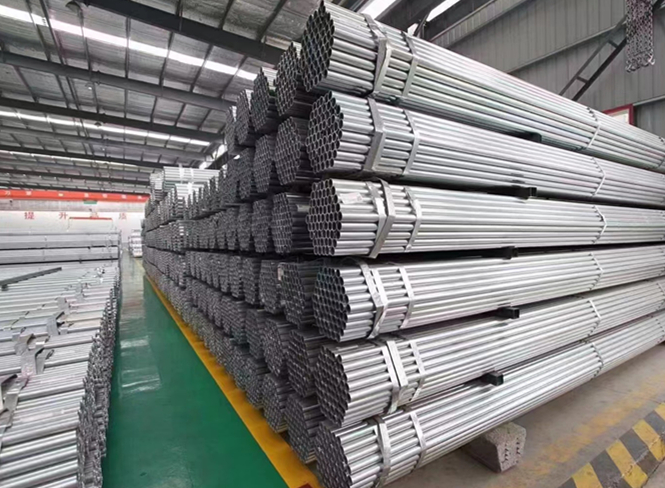

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm. There are different grade of scaffolding tube, such as S235, S355. Our factory has more than 15 years experience in Scaffolding tube, we can produce EN39, EN10219, BS1139 and JIS3444 standard tube. All are produced strictly according to the standard. Usually the surface is hot dipped galvanized with zinc coating above 210g/m2, which offers long term corrosion resistance.

Our scaffolding tubes are manufactured to comply with various international standards such as EN39/BS1139, ensuring quality and safety in construction projects. The production of these steel tubes involves strict testing to ensure their quality and performance. For instance, some manufacturers conduct tests on the chemical composition, physical properties, welding lines, and assembly inspections of the raw materials, and perform load capacity testing for all orders before production and shipment. These steel tubes are typically produced using the hot-dip galvanizing process to enhance their corrosion resistance and durability. The thickness of the galvanized layer is usually not less than 40 microns. Product testing and compliance conform to the EN39:2001 grade S235GT or BS EN10219-1 grade S355JOH. We test the chemical components and tensile test every order and ensure all tubes complying to the S235GT steel grade.

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm. There are different grade of scaffolding tube, such as S235, S355. Our factory has more than 15 years experience in Scaffolding tube, we can produce EN39, EN10219, BS1139 and JIS3444 standard tube. All are produced strictly according to the standard. Usually the surface is hot dipped galvanized with zinc coating above 210g/m2, which offers long term corrosion resistance.

From Tianjin Friend Steel Group, you can get qualifed steel tube to help you get more orders in your market. With rich experience in the market, our sales team provide your professional service.

Standard Compliance: Comply to BS1139 standard to ensure scaffolding tubes are of a high standard, suitable for heavy-duty applications and known for their safety and reliability.

Dimensional Consistency: BS1139 specifies steel tube outer diameter 48.3mm with tolerance +/- 0.3mm and wall thickness 3.2mm at tolerance +/-10%, which are critical for the structural stability of scaffolding systems.

Corrosion Resistance: Galvanized zinc coating around 30-40 micron against rusting and corrosion, ensuring longevity and low maintenance.

Quality Assurance: professional testing and inspection processes during production and galvanization are followed to guarantee steel tube meets the quality standards. 3rd part test report can be provided

Versatility: BS1139 scaffolding tubes are compatible with a variety of scaffold fittings and couplers, offering flexibility in scaffold design and assembly.

BS1139 scaffolding tubes are used across a range of construction and industrial applications, such as:

Supporting temporary work platforms in new builds and renovations.

Providing access for maintenance and repair tasks in industrial and commercial settings.

Serving as a backbone for stage and event structures, offering robust support.

BS1139 scaffolding tubes represent a commitment to excellence in temporary construction support solutions. Their adherence to a recognized standard, combined with their robust design and versatility, makes them a preferred choice for professionals in the construction industry seeking a reliable and safe scaffolding system

| Galvanized Steel Tube Scaffolding Pipe | |

OD | 1.5inch, 1-1/2", 48.3mm, 48.3mm |

Thickness | 3.2mm, 4.0mm |

Length | 1-6m, 5"-21" |

Material | Q235, S235GT, |

Standard | BS1139, EN10025, EN39, EN10219, JIS G3444 |

Surface | hot dipped galvanized |

Zinc Coating | 180-600g |

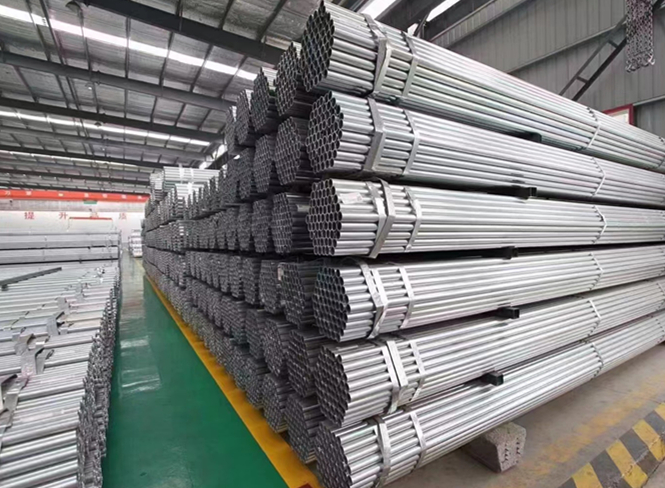

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm. There are different grade of scaffolding tube, such as S235, S355. Our factory has more than 15 years experience in Scaffolding tube, we can produce EN39, EN10219, BS1139 and JIS3444 standard tube. All are produced strictly according to the standard. Usually the surface is hot dipped galvanized with zinc coating above 210g/m2, which offers long term corrosion resistance.

Our scaffolding tubes are manufactured to comply with various international standards such as EN39/BS1139, ensuring quality and safety in construction projects. The production of these steel tubes involves strict testing to ensure their quality and performance. For instance, some manufacturers conduct tests on the chemical composition, physical properties, welding lines, and assembly inspections of the raw materials, and perform load capacity testing for all orders before production and shipment. These steel tubes are typically produced using the hot-dip galvanizing process to enhance their corrosion resistance and durability. The thickness of the galvanized layer is usually not less than 40 microns. Product testing and compliance conform to the EN39:2001 grade S235GT or BS EN10219-1 grade S355JOH. We test the chemical components and tensile test every order and ensure all tubes complying to the S235GT steel grade.

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm. There are different grade of scaffolding tube, such as S235, S355. Our factory has more than 15 years experience in Scaffolding tube, we can produce EN39, EN10219, BS1139 and JIS3444 standard tube. All are produced strictly according to the standard. Usually the surface is hot dipped galvanized with zinc coating above 210g/m2, which offers long term corrosion resistance.

From Tianjin Friend Steel Group, you can get qualifed steel tube to help you get more orders in your market. With rich experience in the market, our sales team provide your professional service.

Standard Compliance: Comply to BS1139 standard to ensure scaffolding tubes are of a high standard, suitable for heavy-duty applications and known for their safety and reliability.

Dimensional Consistency: BS1139 specifies steel tube outer diameter 48.3mm with tolerance +/- 0.3mm and wall thickness 3.2mm at tolerance +/-10%, which are critical for the structural stability of scaffolding systems.

Corrosion Resistance: Galvanized zinc coating around 30-40 micron against rusting and corrosion, ensuring longevity and low maintenance.

Quality Assurance: professional testing and inspection processes during production and galvanization are followed to guarantee steel tube meets the quality standards. 3rd part test report can be provided

Versatility: BS1139 scaffolding tubes are compatible with a variety of scaffold fittings and couplers, offering flexibility in scaffold design and assembly.

content is empty!